Improvement in Brine Management through Pexgol Piping

The impact of Pexgol piping on pump performance improvement and maintenance cost reduction at Sales de Jujuy.

Case Study Nº

128

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

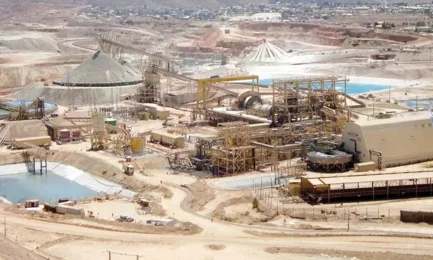

Sales de Jujuy S.A. is the operating company of the main Olaroz Lithium Project by Orocobre in Argentina. This facility is located in the province of Jujuy, at an altitude of 3,900 meters above sea level, and produces lithium carbonate from the brine of the Olaroz Salt Flat, which contains high concentrations of lithium and potash. The transportation of brine from the lithium well posed a significant challenge for the company.

The problem lay in the existing HDPE pipeline, which experienced a pump performance drop three times a month when pumping brine. This situation was caused by pipe clogging due to scale buildup, requiring cleaning that consumed six working days per month. This not only disrupted regular operations but also incurred significant costs for the company.

Pexgol Solution

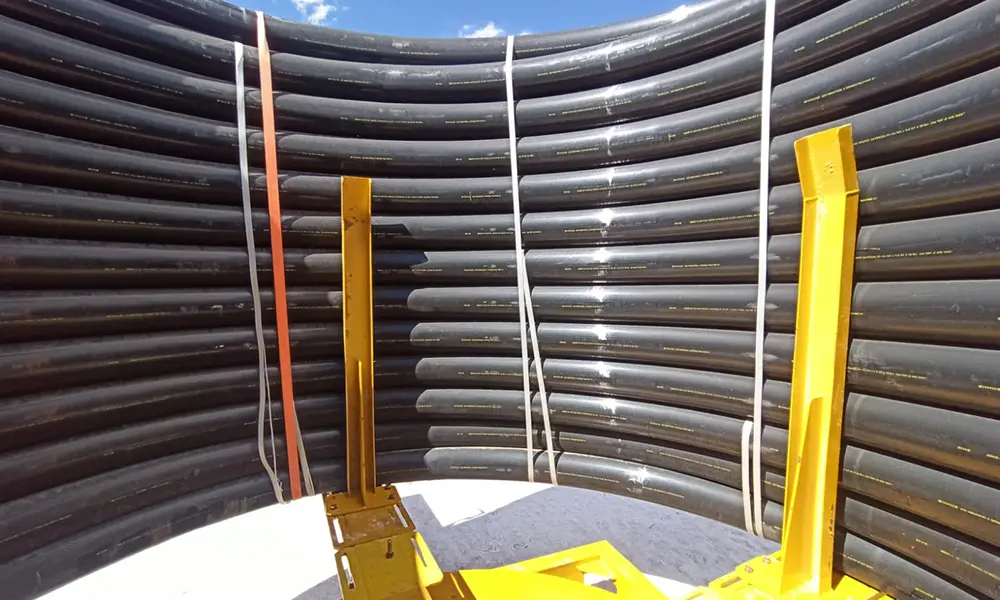

To address this challenge, Sales de Jujuy decided to switch to 160 mm Pexgol piping. They installed 2650 meters of this piping, using double mechanical connectors.

The choice of Pexgol was due to several advantages that this product offered. Firstly, its quick installation significantly reduced the time required for project implementation. Additionally, Pexgol piping is known for its low roughness, which considerably reduces scale buildup.

This change to Pexgol brought immediate and significant results. Line cleaning times and the number of interventions were drastically reduced. In fact, the cleaning time was reduced to only two hours per month, and only at the connections.

Related Case Studies

Water Transport with Low pH Level

|

Революция в транспортировке воды компании Newmont с помощью труб Pexgol

|

Pexgol Piping for Fire Network System Expansion

|

Streamlining Water Supply in Highway Construction

|

Технологическая вода — транспортировка рассола

|