Slurry Transportation

Replacement of HDPE Pipe for Pexgol

Estudo de Caso Nº

36

Cliente

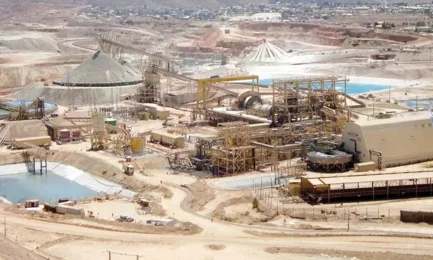

Tizapa Mine

Mexico

|

2015

Condições de Trabalho

Pressure 100 Psi; Flow 225 mД/h; Specific Weight 1.2 t; Solids 20-30%.

Solução Pexgol

Pexgol 10” 250 mm, Class 15 (SDR 11).

Aplicação

Slurry transportation.

Comprimento

200 meters.

Categorias

The Challenge

Tizapa Mine formerly installed an HDPE line were they used to transport slurry. This pipe suffered several failures on the joints, so did the thermo-fusions and the stub-ends as well.

They determinate that the failures were caused by small water hammers on the line.

Pexgol Solution

Due to this special circumstances, Tizapa Mine decided to install Pexgol pipes for the following reasons:

- Supplied in long lengths coils: Of 100 meters each, reducing possible failures in the joints.

- It high resistance to water hammers.

- Burst pressure: 3 times higher than nominal pressure.

- Safe joints: They don’t deform neither detach caused by a pressure surge.

- Quick installation: Coils were uncoiled in 1.5 work hours, without any complex equipment.

Estudos de Caso Relacionados

Water Extraction from Wells

Andacollo Mine

Chile

|

2015

Fish Oil Transport at 36°C / 96.8°F

Guaymas Protein Company

Mexico

|

2018

Carriage of Chemicals at Sea Port

Ashdod Sea Port

Israel

|

2016