Pexgol for Centrifugal Pump Test

Replacement of Steel Pipes with Pexgol for Testing Centrifugal Pumps.

Estudo de Caso Nº

107

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

The Challenge

Flowserve is an American multinational corporation and one of the largest providers of industrial and environmental machinery such as pumps, valves, mechanical end seals, automation, and services to the power, oil, gas, chemical, and other industries.

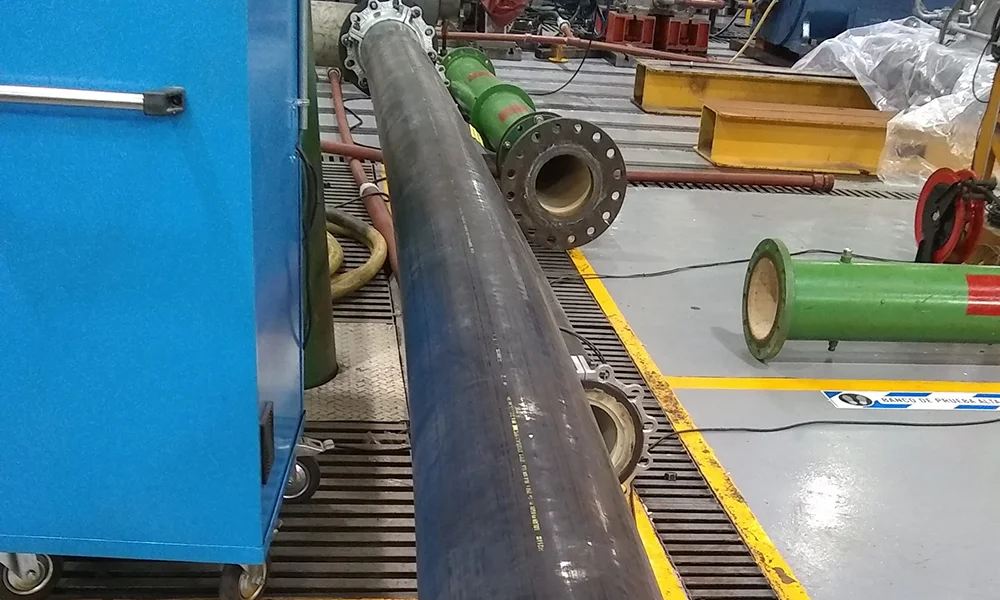

To carry out tests on centrifugal pumps in the laboratory, the company used 10-inch carbon steel pipes. As the design is different in each case, the assembly and disassembly of very heavy pipes were periodically required with the risk that this implies. It was also necessary to use chemical products to prevent corrosion of the pipe.

Pexgol Solution

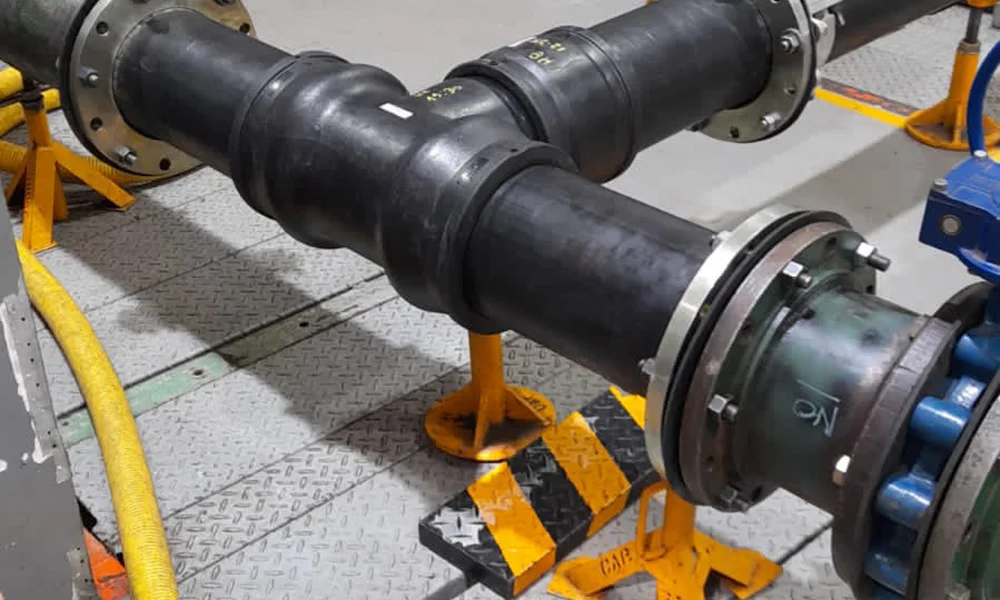

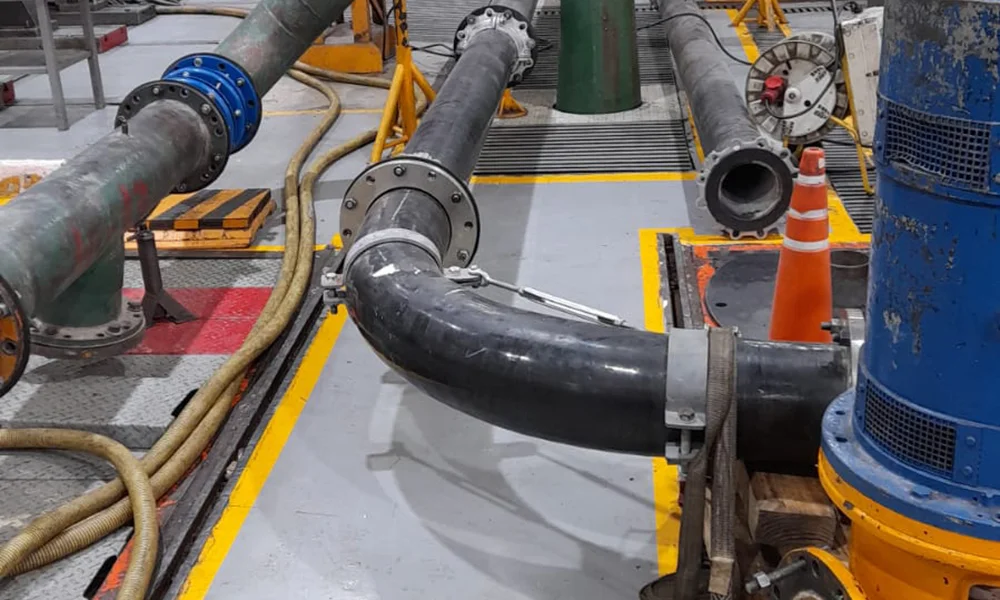

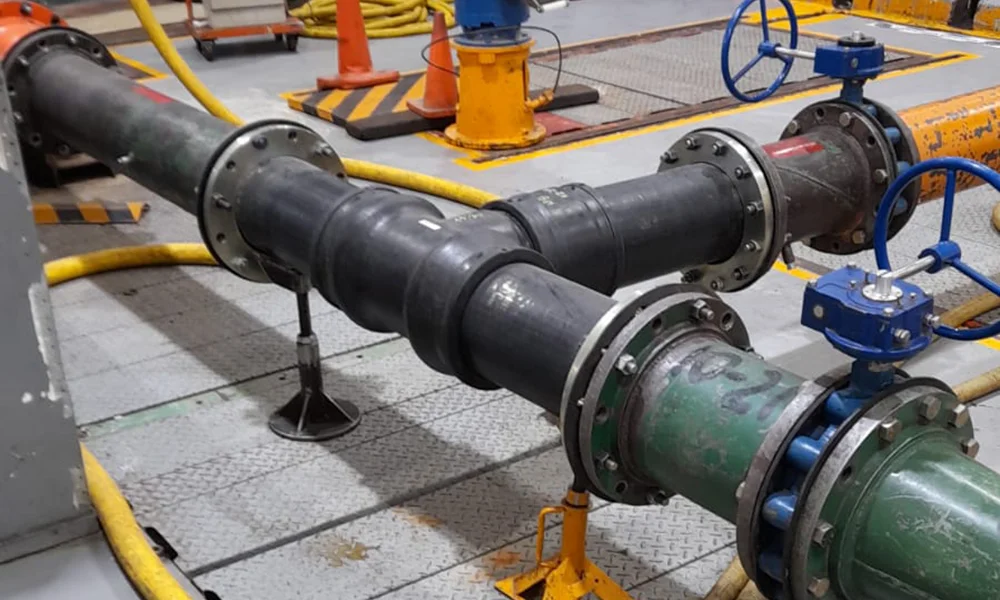

The client decided to replace its carbon steel pipes with Pexgol. Since they are 6 times lighter than carbon steel pipes. Therefore, they allowed to reduce the assembly and disassembly times, with less personnel and lower risks of accidents for the operators. On the other hand, the problem of corrosion that attacked the steel pipes was completely ruled out.

The joints used at the ends of the pipes were flanged mechanical couplings. In addition, Tee fittings and flanged Pexgol elbows were used.

Estudos de Caso Relacionados

Transportation of sodium sulfide

|

Cold Water Distribution for External Cooler System

|

High-pressure fluid transport

|