Open Cast Mine Dewatering

Dewatering With Low Ph Levels

Estudo de Caso Nº

34

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

The Challenge

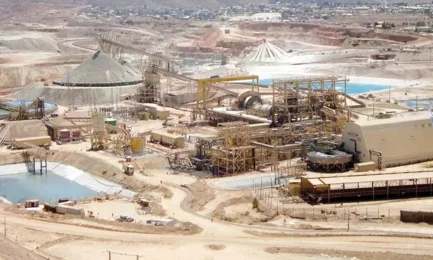

Arcerlor Mittal required to dewater their open cast mine, due to the contamination produced by the low pH levels of the water.

The open cast was 220 meters depth with an 80° slope. From the client point of view, installing a regular pipe would involve doing more than 22 joints, on a harsh ground that was also dangerous for the people that work there. In addition, a regular pipe might need to be supported every 12 meters so it will not collapse due to its own weight.

Pexgol Solution

Pexgol pipes were the optimal solution for this project, because it can be supplied in long lengths coils that makes the whole installation easier.

Pexgol is also known for its stress resistance, Pexgol’s crosslinking piping solution can withstand high amounts of axial and radial stresses, it only stretches up to 2% of its own length and it is capable to hold its own weight plus the water column.

Due to it great flexibility, the coil was uncoiled hundreds of meters away from the installation place, and it was dragged after to the right spot.

In order to descend the pipe through the open cast, it required only chains and a backhoe to hold it. Arcelor Mittal was very satisfied with the installation process, which was simple, and from their point of view, impossible to do it with other type of pipe.

Estudos de Caso Relacionados

Dewatering Through Shafts

|

Efficient and Safe Irrigation in Secondary Leaching with Pexgol

|

Water Extraction from Wells

|