High Pressure Drain in Underground Mine

Installation of Pexgol Pipesf for the Drainage of an Underground Mine.

Estudo de Caso Nº

65

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

The Challenge

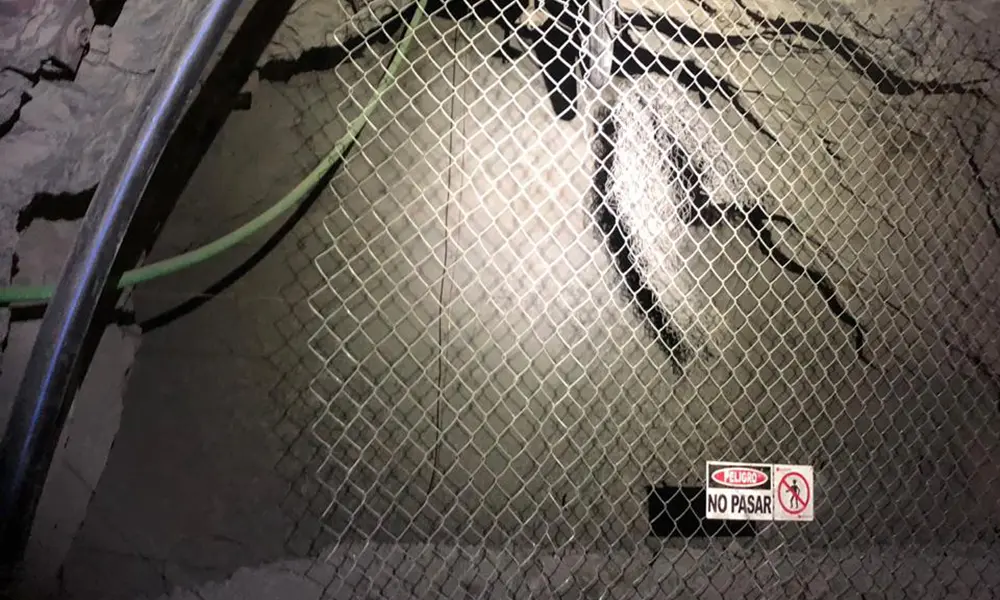

The Ojos del Salado mine (Lundin Mining) required the installation of a line for the drainage of high pressure water from the lower mine level, through the vertical ventilation chimney, with a height of 30 meters.

Primarily the client faced time problems on one hand and on the other hand needed the pipeline to be installed in the shortest time possible, without interfering with the mine’s operation.

Pexgol Solution

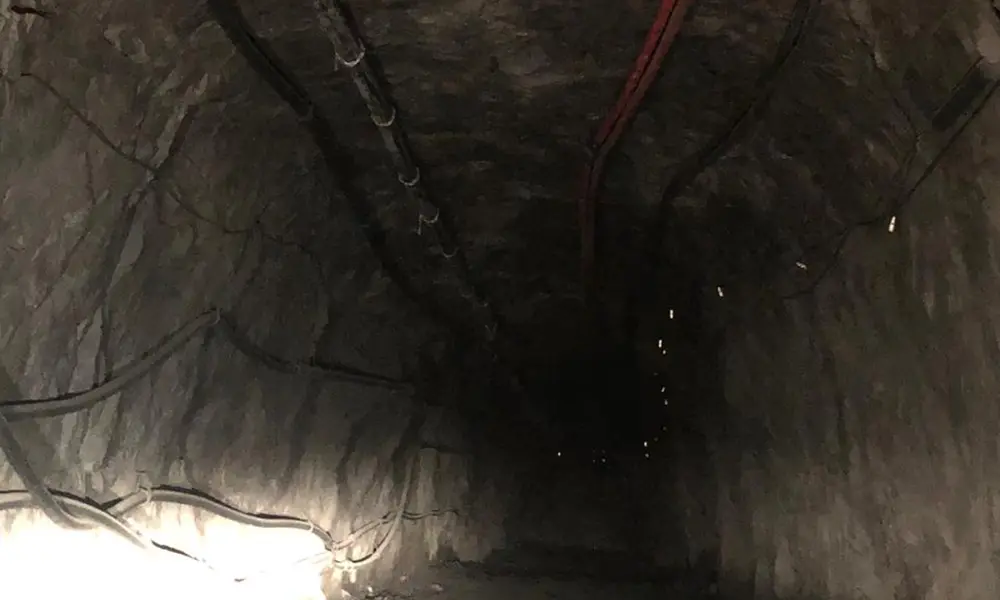

It was decided to install a 600 m line of Pexgol 160 mm (6″) class 24 pipe for drainage due to its long length supply format, ease of installation, flexibility contributing to easy accommodation into the curves of the mine interior. Furthermore, due to limited installation times operation stops could be avoided.

It took only 2 days to uncoil and assemble the pipe. For reasons of convenience and at the request of the Prevention Department, the pipeline was placed in sections of 150 meters, since it had to be pulled a 5 km long ramp from the mine interior to the installation point.

Under the same conditions when installing HDPE pipeline, it would have taken about 1 week only to prepare the sections before installing them inside the mine and furthermore only shorter sections could have been installed due to the rigidity of the material.

Estudos de Caso Relacionados

Pexgol Piping for Fire Network System Expansion

|

Transportation of sodium sulfide

|

Installation of Water Well in Reduced Space

|

Mineral Processing – Potash Processing Plant

|

Pioneering Space Launches with Ground-breaking Piping Solutions

|