From carbon steel to Pexgol: A victory against corrosion

Pexgol helped Profertil to overcome the corrosion challenge in its fire protection network.

Estudo de Caso Nº

133

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

The Challenge

Profertil, a leading producer and supplier of soil nutrients with an annual production capacity of 1,320,000 tons of Urea and 790,000 tons of ammonia, faced a critical challenge at their Bahia Blanca facility in Argentina in 2021. The fire protection network in their plant, originally made from carbon steel, was highly susceptible to corrosion due to two distinct factors: the hardness of the water running through the pipes, causing internal corrosion, and the high salt content in the coastal soil, inducing external corrosion. This corrosion was causing leaks in the pipes, compromising the effectiveness of their crucial fire protection network.

Pexgol Solution

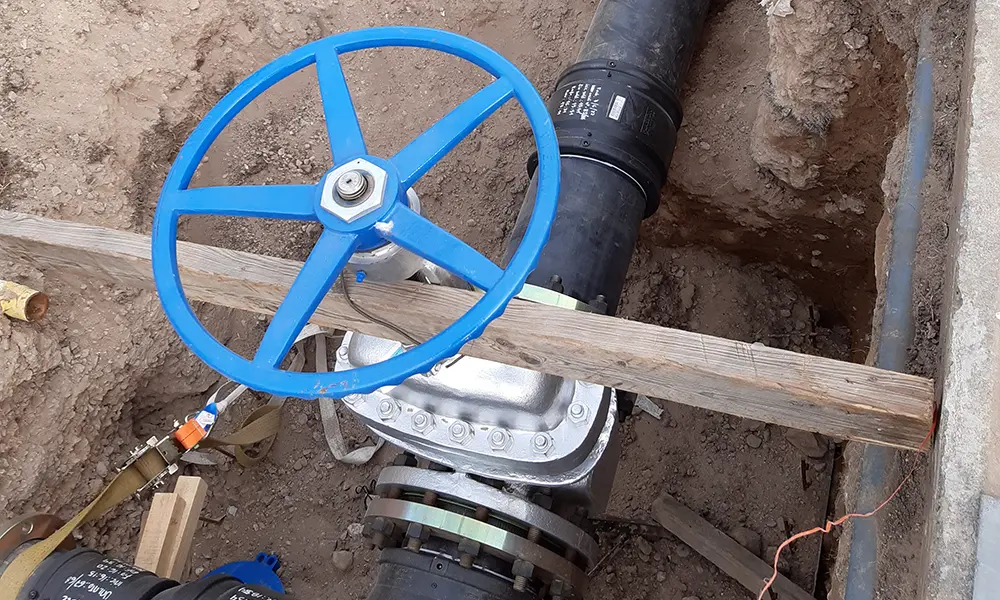

Pexgol provided an effective and efficient solution to Profertil’s problem with its range of corrosion-resistant PE-X pipes. Pexgol pipes of various sizes (63, 180, 225, 250, and 280 mm) were used to replace the 2000 meters (6562 feet) of the existing fire protection network.

Pexgol’s fusion couplers, flange couplers, PE-X coated fittings, Pexgol reducers, Pexgol elbows, and fire hydrant connectors were used in the installation process. The installation was smooth and straightforward, thanks to Pexgol’s flexible material that offers rapid installation and reliability, a major advantage over the previous carbon steel system.

The local team, ArgPex, provided ongoing support throughout all stages of the project, from engineering and logistics to installation and commissioning, ensuring that the customer was well-guided and supported throughout the entire process.

Opting for Pexgol’s solution not only provided a system resistant to the corrosive effects of hard water and salty soil, but also a solution with a longer life span and fewer interferences within the plant, due to the flexibility and durability of Pexgol pipes. This successful replacement has set a new standard for Profertil’s operations, highlighting the effectiveness of Pexgol’s innovative approach to corrosion-resistant pipe systems.

Estudos de Caso Relacionados

Fish Oil Transport at 36°C / 96.8°F

|

Implementation of Pexgol Pipelines for the Transport of Muddy Water

|

High Corrosion Resistance Against Brine

|

Transport of Muddy Water in a Palm Oil Processing Plant

|