Leached Slurry Transportation

Slurry transportation with high nickel levels

Estudo de Caso Nº

18

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

The Challenge

Moa Nickel used to transport leached slurry from the tubular reactors to the CCD thickener feed line. This process caused several issues on different pipe materials. The transported fluid was composed by:

- 28-32 g/l acid

- 1,00 g/l N

- 0,54 g/l Co

- 1,00 g/l Fe

- 21,00 g/l SO4

- 30,0 g/l free acids

- Solids: 0,086% Ni, 0,013% Co, 46,00% Fe

Previously, titanium Sch20 pipes were installed, but if suffered deformations and it needed to be repaired constantly. The titanium pipe was replaced for a stainless steel pipe 316 Sch40, and it lasted 8 years and it finally required to be replaced because it presented wear issues.

Pexgol Solution

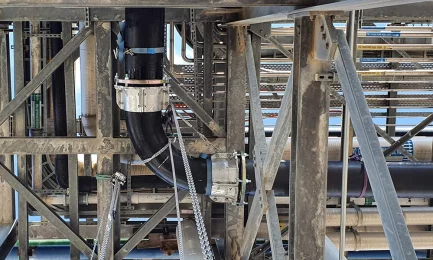

Golan provided 11.8 meters of pipes sections with mechanical joins that could resist corrosion, high temperatures and wear with no effort.

Regarding the prices per meter, installation costs and maintenance, versus stainless steel and titanium pipes, Pexgol proved to be the most convenient option.

Estudos de Caso Relacionados

Hot Water Distribution for Solar Technology

|

Industrial Waste Water to MBR Treatment Facility

|

Improving efficiency in steel foundry with Pexgol

|