Extraction of Underground Water

Extraction of underground water through wells

Estudo de Caso Nº

24

Cliente

|

Condições de Trabalho

Solução Pexgol

Aplicação

Comprimento

Categorias

The Challenge

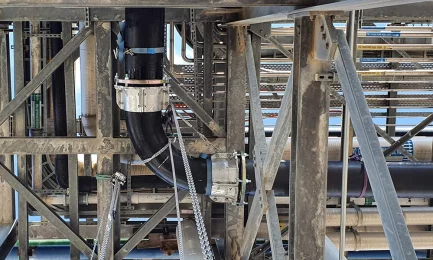

Collahuasi Mine extracted process water through wells, they used a galvanized steel pipe. This pipe had several failures on its joints and demanded a long time installation process (around 3 days).

The client required a more flexible pipe, with longer working life than the steel, in order to keep the operations stable and minimized the stops in the plant for maintenance.

Pexgol Solution

A Pexgol pipe was installed in less than 3 hours, reducing 24 times the average installation time. Its weight was lighter than steel (70% less), so it involved less workers, less tolls, and less equipment to leave the well full operative. During the working life of the well, the Pexgol pipe didn’t require any sort of maintenance, and it was employed after in another application at the plant.

Estudos de Caso Relacionados

Industrial Waste Water to MBR Treatment Facility

|

Transport of Silica Arena: HDPE vs Pexgol

|