Newmont’s Water Transportation Revolution with Pexgol Pipes

Securing the future of gold mining: Newmont Corporation chooses Pexgol for water transport

Case Study Nº

132

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

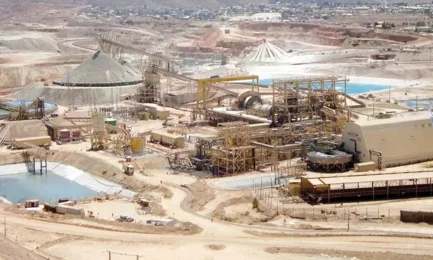

Newmont Corporation, the world’s largest gold mining company, faced a significant challenge at its Cerro Negro unit in Santa Cruz, Argentina. The task at hand involved the transportation of water across challenging foothills terrain, a critical aspect of its mining operations. Given the demanding conditions, the ideal solution required pipes with superior durability, quality assurance for water installations, and agility for deployment and assembly. The initial plan involved over 300 joints, each representing a potential point of failure, and thus, a high risk to operational efficiency and reliability.

Pexgol Solution

Pexgol emerged as the most suitable solution for this task. Its range of pipes – Pexgol 63, 75, 90, 110, 160, 200, and 250 in classes 10, 12, and 15 – was chosen for their unmatched resilience, quality, and ease of installation. By supplying the pipes in rolls, several joints were eliminated from the pipeline, significantly reducing the risk of failure and decreasing installation time by 80% compared to other plastic pipes.

Pexgol’s permanent consultancy and training for the installers, coupled with its quick product availability, made it the perfect choice for Newmont Corporation. Additionally, Pexgol’s unique ability to avoid joints contributed to the ease, agility, and security of the pipeline, making cross-linked polyethylene (PEX) the most versatile and cost-effective solution for this project.

The installation process unfolded seamlessly. Newmont Corporation facilitated the uncolling of the Pexgol pipe coils, initially estimated to use 250 joints. The timeline for the installation was duly adhered to, with the entire pipeline spanning 5500 meters (approximately 18045 feet).

The utilization of Pexgol pipes effectively addressed Newmont Corporation’s water transportation needs, optimizing their gold mining operations’ efficiency, and contributing to its sustainable mining practices.

Related Case Studies

Scaling Up Efficiency: District Energy at Penn State Harrisburg

|