Hot & Abrasive Potash Brine Processing

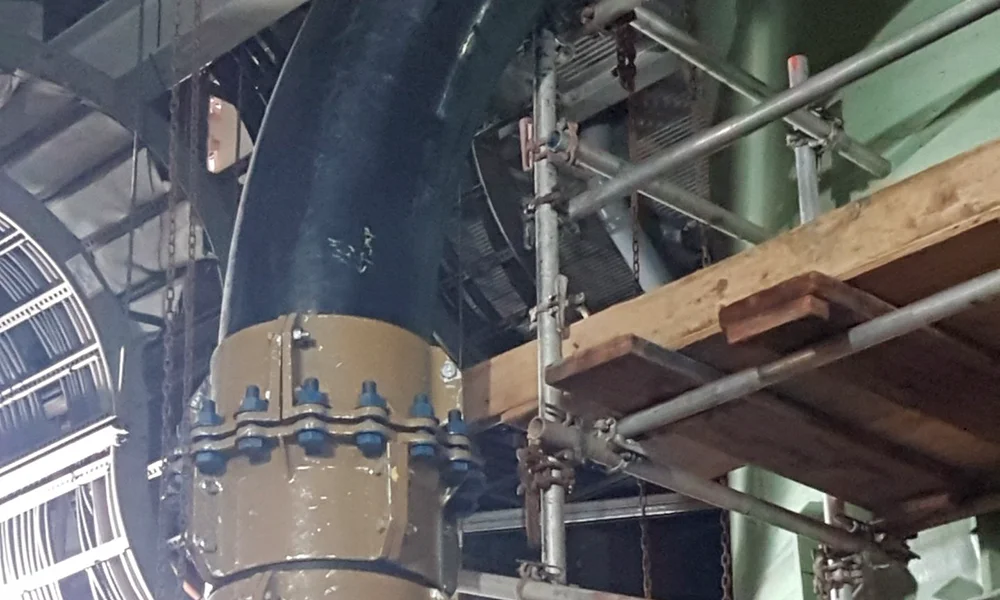

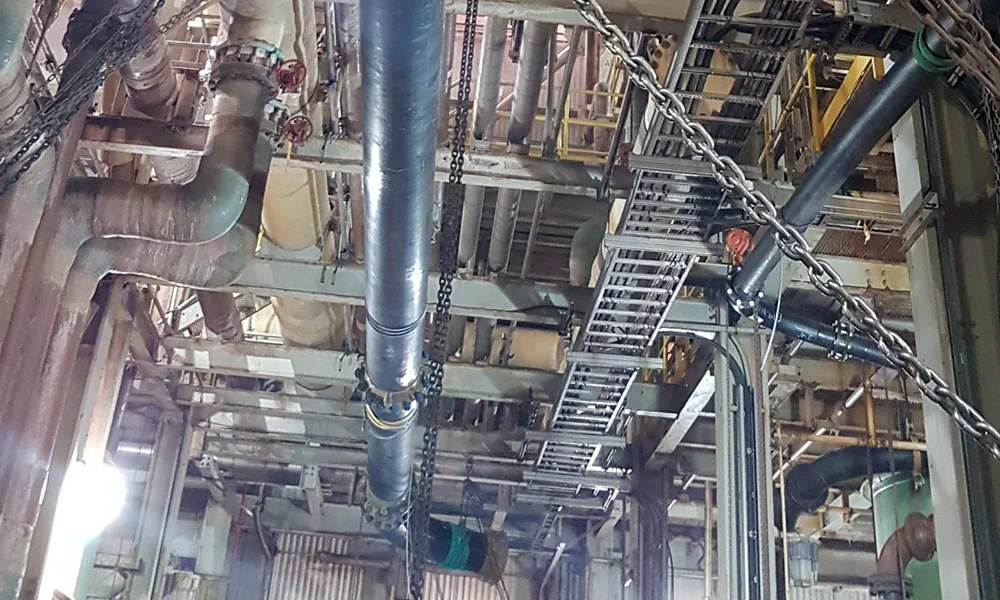

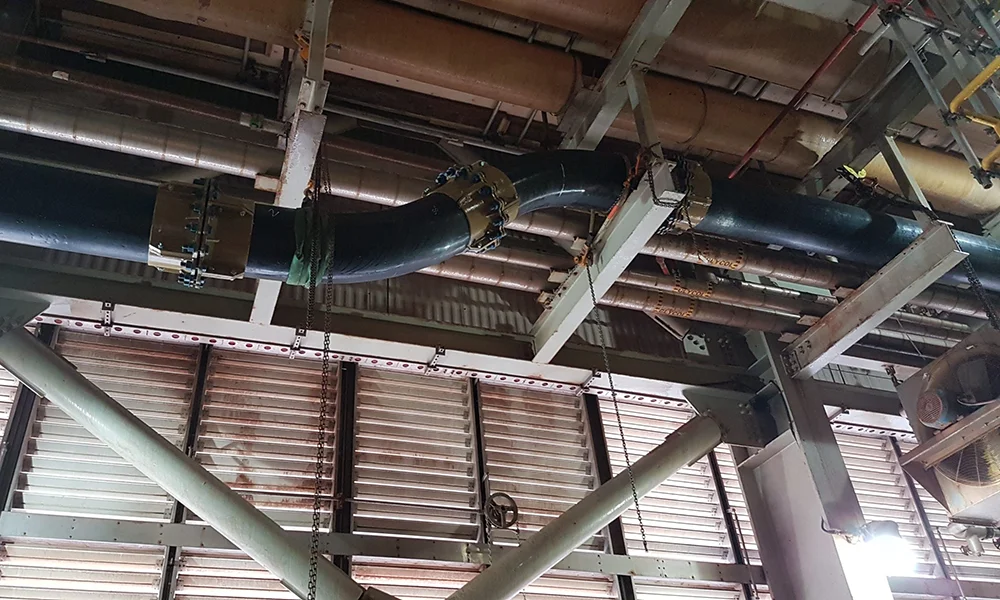

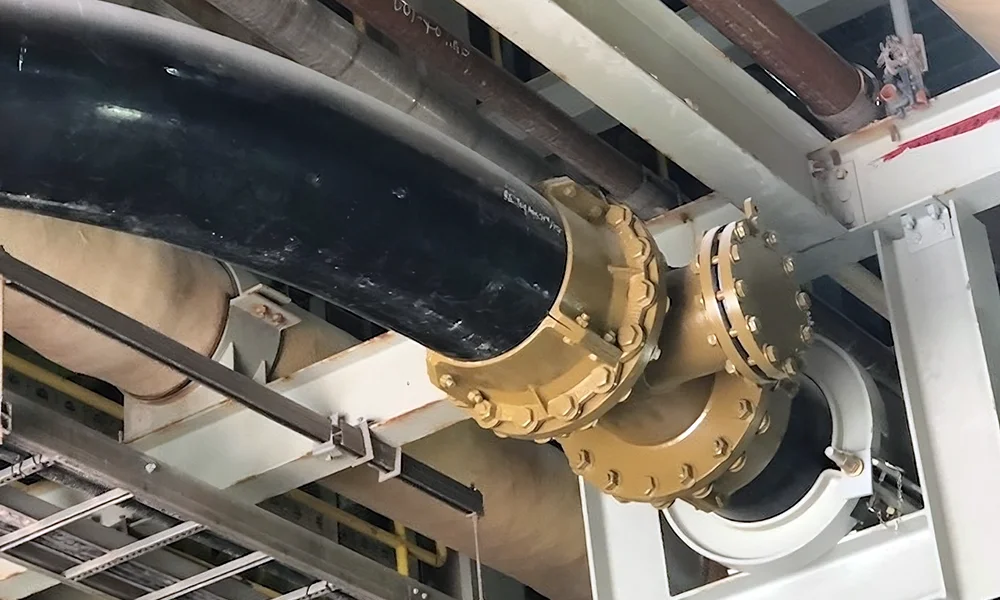

Installation of Pexgol Pipe for a Intake Line to Transport Hot Abrasive Brine Slurries

Case Study Nº

87

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

A Canadian fertilizer company, and the largest producer of potash and the third largest producer of nitrogen fertilizer in the world, required to transport hot ore and brine in their facility in Saskatoon, Saskatchewan.

This was a new intake line. The facility traditionally used FRP and rubber-lined steel pipes. The FRP stress cracking issues and failure mechanism were a concern, and the client wanted to move away from it, but the conditions made material selection challenging.

The new line required to been able to transport saturated chloride brine at elevated temperatures with high resistance to abrasive slurries.

Pexgol Solution

The design of the line was carried out by the engineering company Wood Plc (then AMEC-FW) and Pexgol was selected. Pexgol went through several verification stages to ensure material suitability and verify design parameters:

- Temperature and pressure suitability.

- Abrasion resistance comparison with FRP, PP-RCT and other materials.

- Expansion restraining forces analysis.

- Support Distance Verification.

The system required a variety of nonstandards elbows, which were made by Golan’s Application Team.

The reliability of Pexgol during the last years has motivated the client to continue with their material reliability improvements in other parts of the facility, and other sites.

Related Case Studies

Transport of Compressed Air for Underground Mine

|

Syncrude & Pexgol: A Collaboration Set to Reshape Slurry Transport

|

Transport of Compressed Air for Underground Mine

|

Syncrude & Pexgol: A Collaboration Set to Reshape Slurry Transport

|

Transport of Compressed Air for Underground Mine

|

- 1

- 2

- 3

- 4

- 5

- 6