Enhancing Nexa Resource’s Waste Management Using Pexgol Pipes

Pexgol’s piping system enabled Nexa Resources to revamp their waste management process, significantly reducing environmental impact.

Case Study Nº

130

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

Nexa Resources, a global mining and metallurgy leader, was seeking innovative ways to reduce the environmental impact of its Tres Marias mining unit, located in Bello Horizonte, Brazil.

An integral part of this plan involved a significant adjustment to their waste management strategy. The team aimed to eliminate the existing tailings dam by transporting a mixture of dam water and pulp to a filtration plant. Here, the water was to be separated and reused, and the pulp transported to a drying plant for repurposing. However, the transition necessitated a reliable, resilient, and efficient piping system that could support the transportation of pulp—a zinc hydrometallurgy waste—over a distance of approximately 1240 meters (or about 4068 feet).

Pexgol Solution

Pexgol was chosen as the ideal solution for this challenging operation. Two pipe dimensions—Pexgol 180 mm and Pexgol 250 mm, class 15—were provided in coils ranging from 200 to 300 meters (approximately 656 to 984 feet) each. These pipes proved perfect for the task at hand, with a fluid temperature tolerance between 25-38°C (77-100.4°F), a flow rate of 190 – 260 m³-h, and pressure between 8 to 12 bar.

Pexgol’s advantages—fast installation and provision of longer lengths—made it an optimal choice for Nexa Resources.

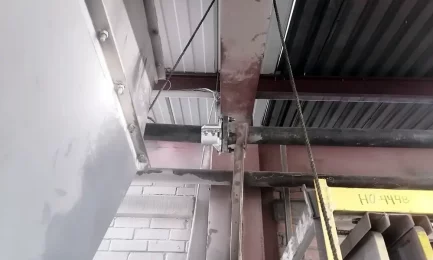

Though initially, there were complications with the electrofusion connections due to the contractor’s unfamiliarity with the process, the Pexgol technical team’s support enabled successful completion of the task. The pipe ends were placed at “registry points” to monitor their operational efficiency, further ensuring a smooth and successful transition.

Pexgol’s solution effectively supported Nexa Resource’s commitment to sustainable mining, providing a reliable, efficient, and durable pipeline for their new waste management process.

Related Case Studies

Water Drainage at an Open-Cast Mine

|

Water Transport in Complex Terrain

|

Improving efficiency in steel foundry with Pexgol

|

Transport of Compressed Air for Underground Mine

|