Transportation of Alcohol for the Production of Rum and Brandy

Transport of Concentrated Alcohol to 86% for the Production of Rum and Brandy

Case Study Nº

54

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

Cuba Ron is the largest producer of rum in Cuba and manufacturer of brands such as Havana Club and Santiago de Cuba.

Cuba Ron needed to transport the rum and brandy between the different areas of the plant and to the cellars. For this application they used stainless steel and carbon steel pipes. Due to the corrosion of the alcohol, which was dangerous for the fluid transport since it could detach particles and affect it. Also, these lines suffered from corrosion on the outside of the pipes as the plant is located in a tropical area near the sea, making the environment corrosive helping the deterioration of the lines.

Pexgol Solution

Cuba Ron then looked for a long-term solution for the replacement of their steel pipes. The main concern when selecting a new pipe material was not affecting the flavor of the rum and brandy that they commercialized worldwide, and to find a pipe material that could withstand the difficult transport conditions for the line.

Therefore, they performed different chemical and taste tests before making the change. They performed tests on PE, ETFE and both suffered a chemical attack. When testing PE-X the tube reacted positively * for both chemical resistance and taste.

Given the excellent results, on-site tests were also carried out with a long-term pipeline.

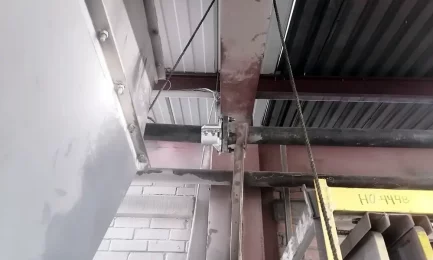

The installation was quick and without complications despite the fact that the plant, being located in Cuba, did not have sophisticated equipment or certified personnel. Pexgol supplied pipes in long sections and mechanical accessories that were very easy to install and did not require any special tools.

The installation helped improve the production of the plant and prompted the client to renew all its lines with Pexgol pipe systems.

(*) The tests were carried out in the laboratories of Golan Plastic Products.

Related Case Studies

Fiber Optic Cables Through a Vertical Shaft

|

Improving efficiency in steel foundry with Pexgol

|

Potable Water Aqueduct

|