New Wastewater Treatment Plant with Pexgol Pipes

The Original Design for a Wastewater Treatment Plant included Stainless Steel Pipes, but after discovering the Superior Capabilities of Pexgol Pipes, the Entire Facility was Switched Over.

Case Study Nº

118

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

Wastewater treatment facilities are critical to public health and the environment, ensuring that our water sources are safe and clean. One crucial aspect of these facilities is their piping systems, which transport wastewater from one stage of the treatment process to another. Traditionally, stainless steel has been the preferred material for wastewater piping due to its strength and durability. However, a wastewater treatment facility in Israel recently decided to switch to PE-X pipes from Pexgol.

Pexgol Solution

There are several reasons why the client decided to switch from stainless steel to Pexgol pipes. First and foremost, Pexgol pipes are significantly less expensive than stainless steel. In addition, they are much more convenient and flexible to work with, allowing for easier final adjustments in the field. This convenience factor is essential in a wastewater treatment facility, where there are often tight spaces and difficult-to-reach areas.

Another benefit of Pexgol pipes is their availability. Unlike stainless steel, Pexgol pipes are readily available, reducing the wait time for installation and maintenance. Finally, Pexgol pipes are absolutely resistant to corrosive conditions, which is critical in a wastewater treatment facility where pipes are exposed to highly corrosive substances.

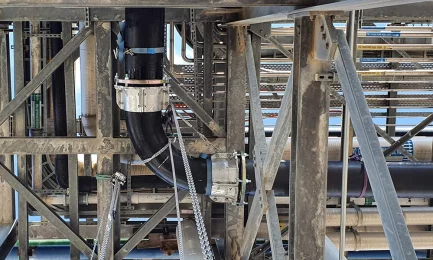

To install the Pexgol pipes, the facility used mechanical fittings such as GP Flange couplers, Mechanical double connectors, brass fittings, and electrofusion Couplers. These fittings are easy to install and provide a secure, leak-free connection between pipes. Overall, the switch from stainless steel to Pexgol pipes has proven to be a wise choice for this wastewater treatment facility, providing significant cost savings and convenience, without sacrificing durability or performance.

Related Case Studies

Industrial Waste Water to MBR Treatment Facility

|

Fish Oil Transport at 36°C / 96.8°F

|