Backfill

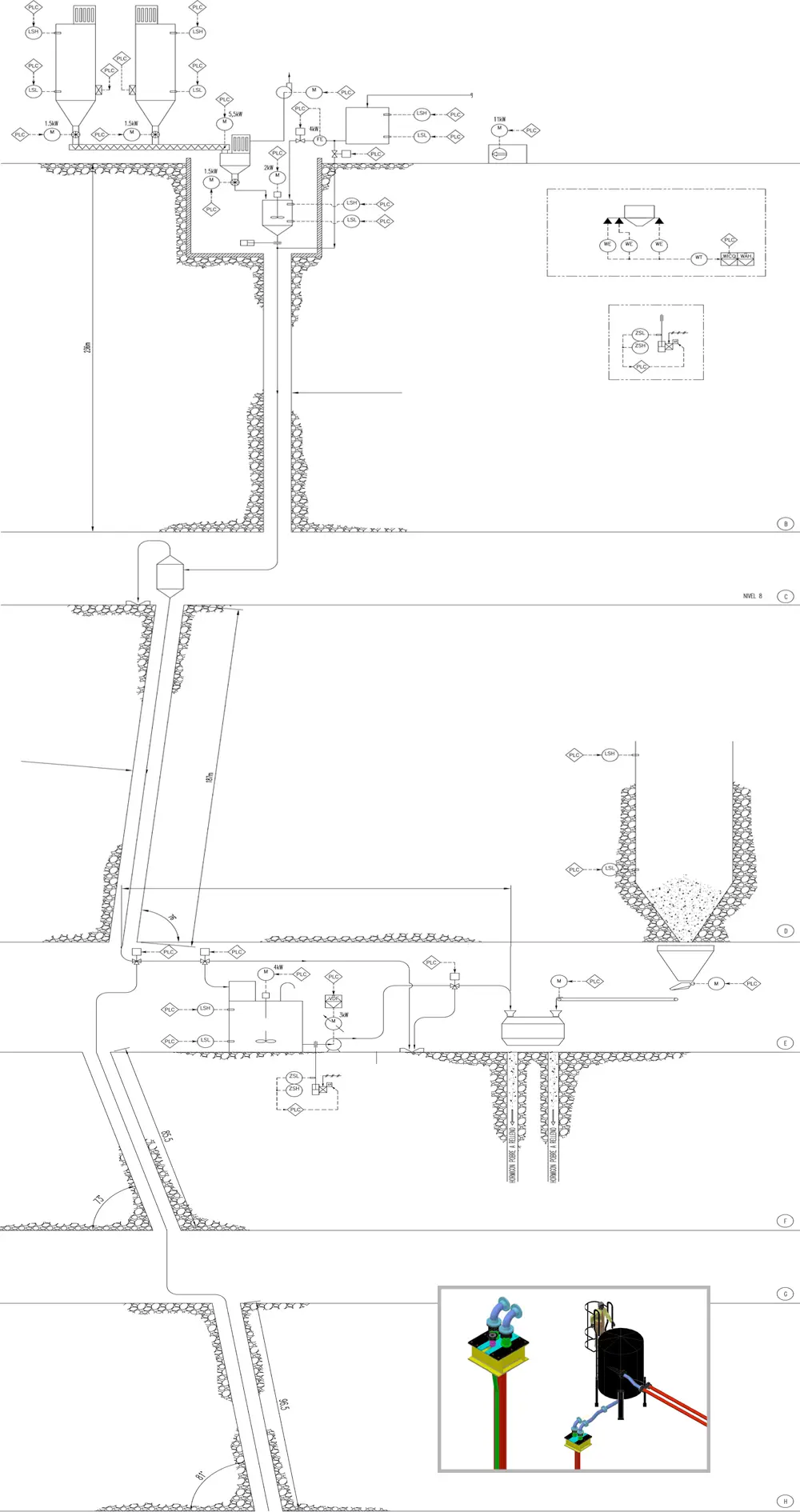

Cement Slurry Injection to an Underground Mine

Case Study Nº

35

Customer

|

Working Conditions

Pexgol Pipes

Application

Lenght

Categories

The Challenge

Due to this special circumstances, the client requested Pexgol pipes since they can be provided in 600 meters sections, they are flexible and highly resistant to abrasion and impacts.

The pipe sections were uncoiled hundreds of meters from the installation place, later they were descended with a hydraulic crane.

The end of the pipe was connected with a conical weight used as a guide to help it descend trough the robbins.

The ground was very harsh with sharp rocks, however the pipes were dragged, pulled and descended without problems.

The pipes were practically hanging from the surface of each level on the mine, supported by electro-fusion couplers. Despite the complicated conditions, the installation took only 60 net hours of work.

Pexgol Solution

Pexgol pipes were the optimal solution for this project, because it can be supplied in long lengths coils that makes the whole installation easier.

Pexgol is also known for its stress resistance, Pexgol’s crosslinking piping solution can withstand high amounts of axial and radial stresses, it only stretches up to 2% of its own length and it is capable to hold its own weight plus the water column.

Due to it great flexibility, the coil was uncoiled hundreds of meters away from the installation place, and it was dragged after to the right spot.

In order to descend the pipe through the open cast, it required only chains and a backhoe to hold it. Arcelor Mittal was very satisfied with the installation process, which was simple, and from their point of view, impossible to do it with other type of pipe.

Related Case Studies

Hot Water Distribution for Solar Technology

|

Potable Water Supply on Harsh Terrain

|

Vertical Solution for Mine Dewatering in Fresnillo

|